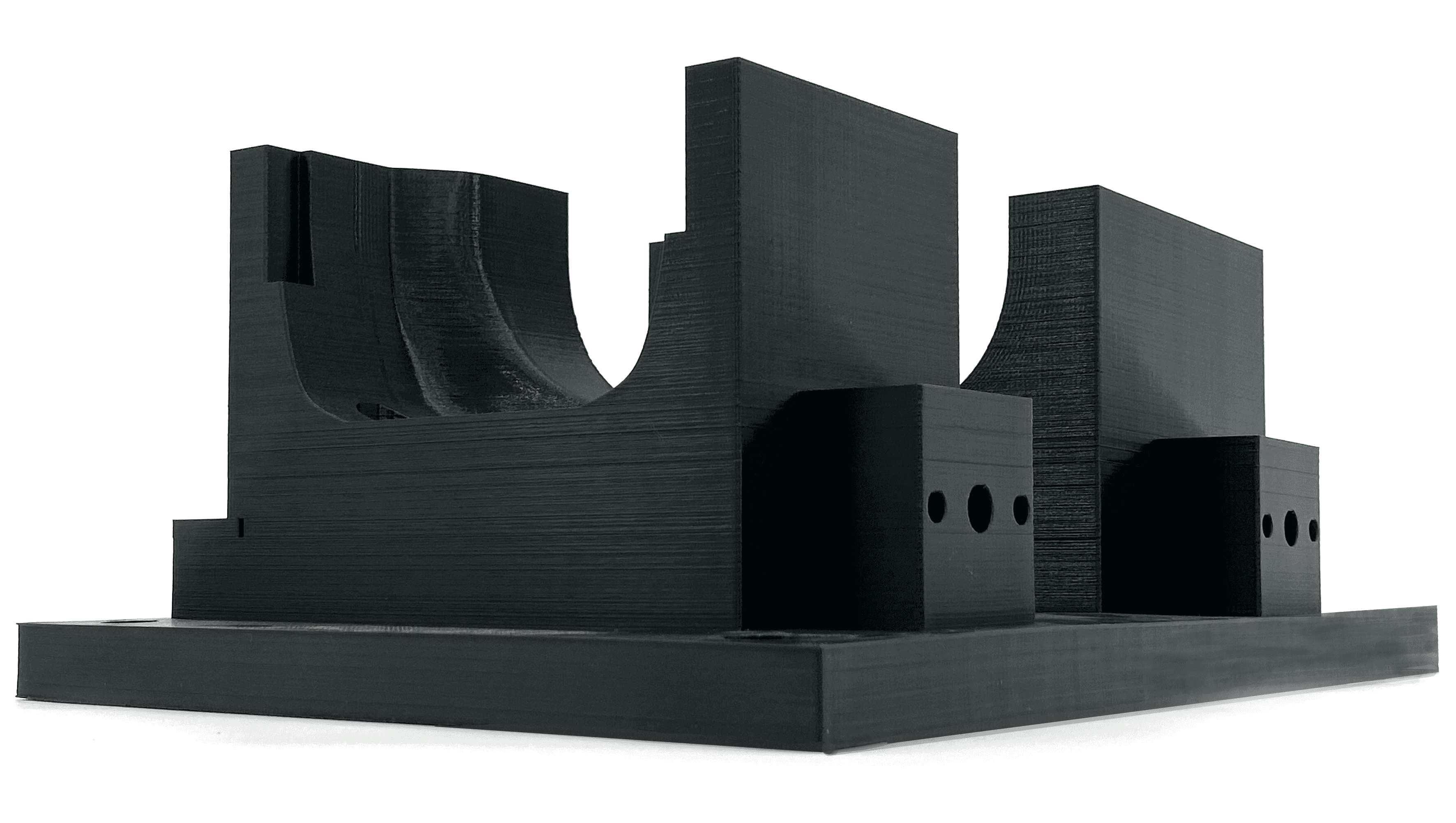

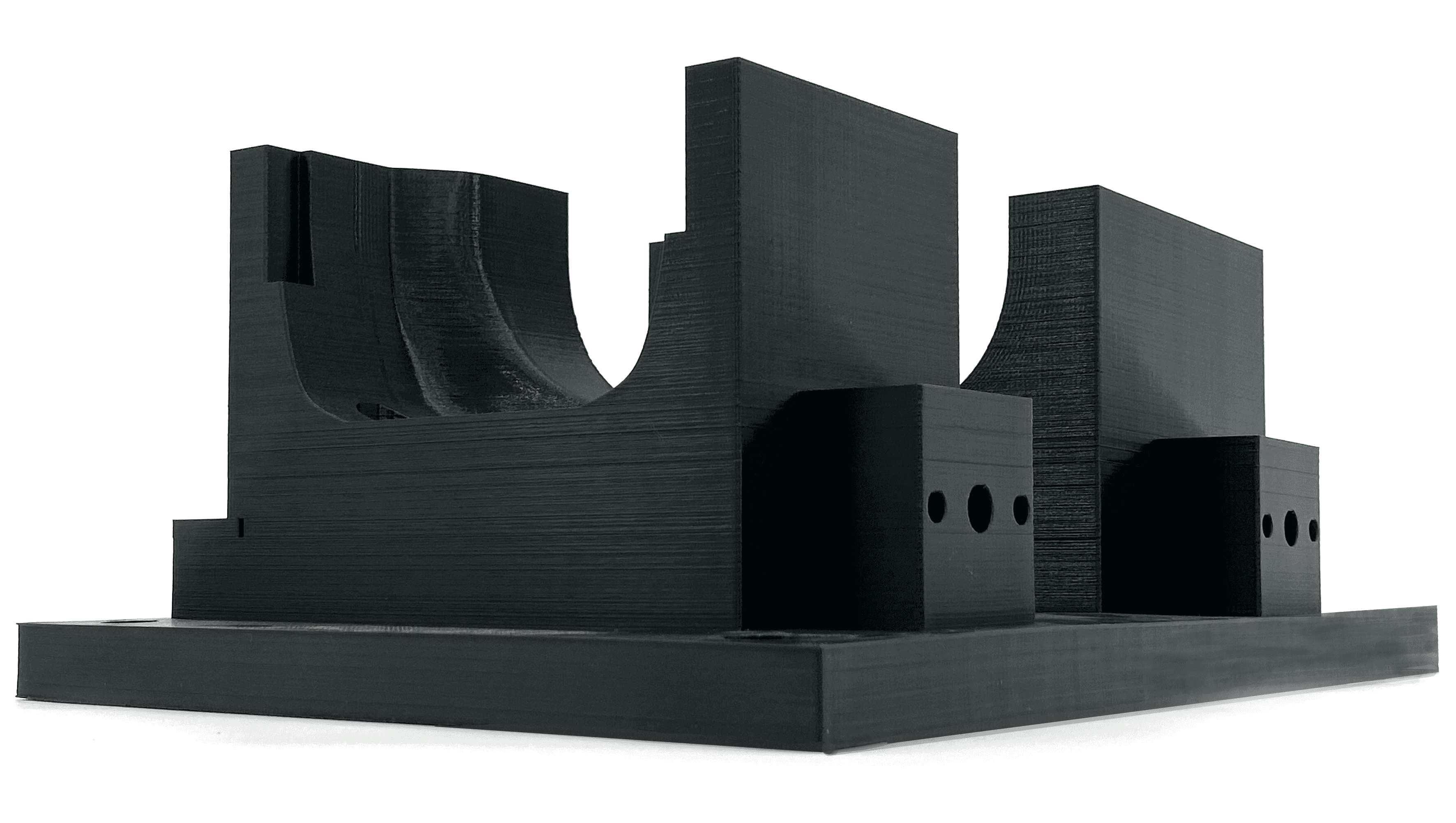

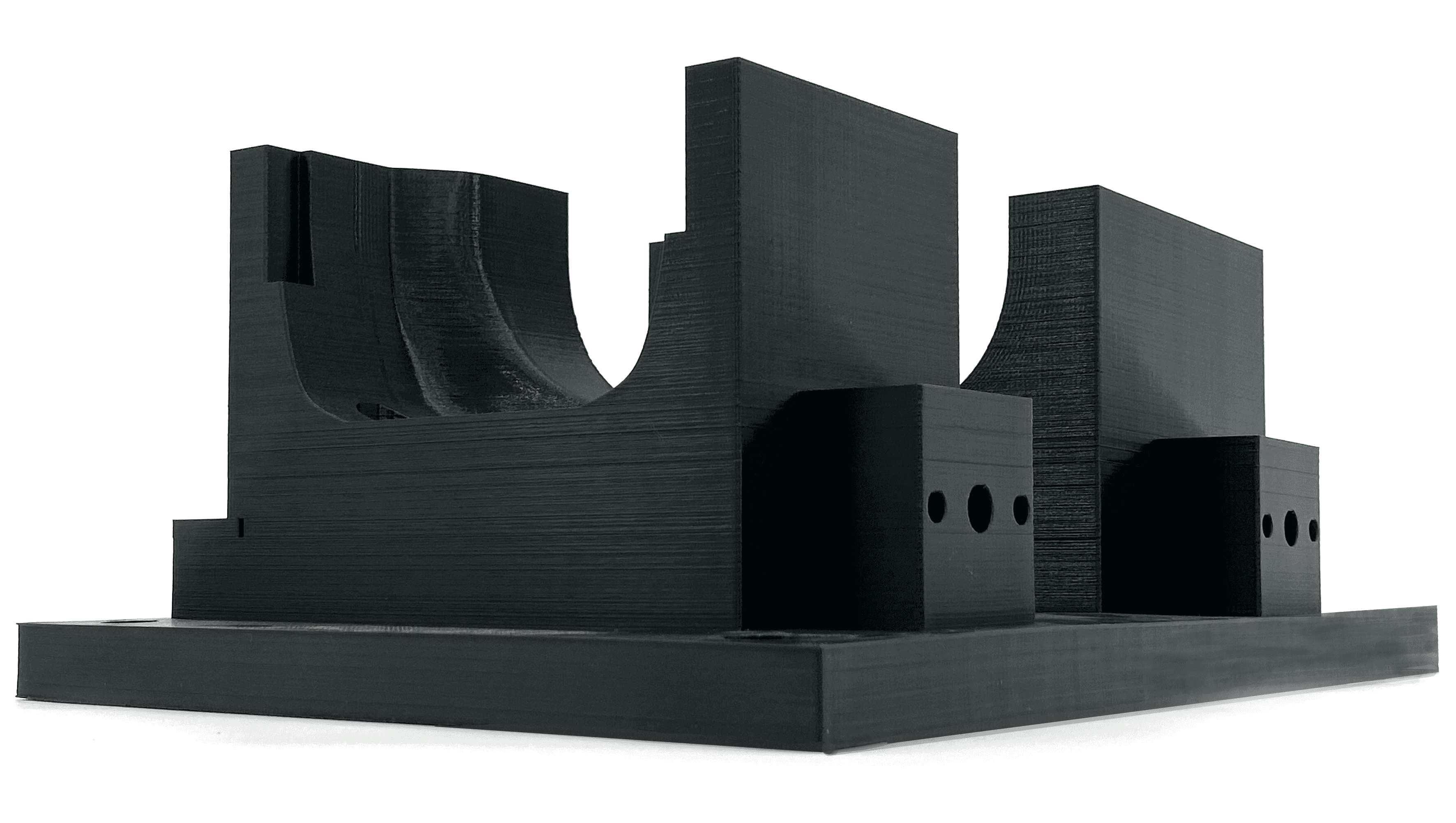

PLA

Technology:

An accurate, cost effective material for low mechanically or thermally demanding applications.

Popular

Great Value

Great for Bulk Orders

Great for Display

Design Review

Make a difference with your production process by choosing PLA. This cost-effective and environmentally friendly material is perfect for basic parts and can be customized with a range of colors. From prototypes to bulk production runs, PLA is the smart choice for your business and the planet.

Ideal Size ≤

600 x 600 x 600 mm

(24 x 24 x 24 in)

Resolution

0.16 - 0.4 mm

Colors

White

Black

Grey

Red

Blue

Orange

Green

Yellow

Teal

Purple

Tan

Wood

Pink

Economical

Max Size

Flexibility

Strength

Heat Resistance

Economical

Label

Max Size

Label

Flexibility

Label

Strength

Label

Heat Resistance

Label

go big!

Use our 600x600x600mm build volume with this incredibly low shrink/warp material.

go big!

Use our 600x600x600mm build volume with this incredibly low shrink/warp material.

go big!

Use our 600x600x600mm build volume with this incredibly low shrink/warp material.

surprisingly functional

Don't let its hobbyist roots fool you. Engineers are finding many uses for PLA.

surprisingly functional

Don't let its hobbyist roots fool you. Engineers are finding many uses for PLA.

surprisingly functional

Don't let its hobbyist roots fool you. Engineers are finding many uses for PLA.

cost effective

As the most affordable FDM material, PLA is your best choice for fast, accurate parts.

cost effective

As the most affordable FDM material, PLA is your best choice for fast, accurate parts.

cost effective

As the most affordable FDM material, PLA is your best choice for fast, accurate parts.

Compare with other

FDM

materials

Material

Economical

Max Size

Flexibility

Strength

Heat Resistance

Specifications

Mechanical Properties

(XY) Tensile Modulus

2636 ± 330 MPa

ISO 527, GB/T 1040

(XY) Tensile Modulus

2636 ± 330 MPa

ISO 527, GB/T 1040

(XY) Tensile Strength

46.6 ± 0.9 MPa

ISO 527, GB/T 1040

(XY) Tensile Strength

46.6 ± 0.9 MPa

ISO 527, GB/T 1040

(XY) Elongation at Break

1.90 ± 0.21 %

ISO 527, GB/T 1040

(XY) Elongation at Break

1.90 ± 0.21 %

ISO 527, GB/T 1040

(XY) Bending Modulus

3283 ± 132 MPa

ISO 178, GB/T 9341

(XY) Bending Modulus

3283 ± 132 MPa

ISO 178, GB/T 9341

(XY) Bending Strength

85.1 ± 2.9 MPa

ISO 178, GB/T 9341

(XY) Bending Strength

85.1 ± 2.9 MPa

ISO 178, GB/T 9341

(XY) Charpy Impact Strength

2.68 ± 0.16 kJ/m²

ISO 179, GB/T 1043

(XY) Charpy Impact Strength

2.68 ± 0.16 kJ/m²

ISO 179, GB/T 1043

Thermal Properties

Glass Transition Temperature

61 °C

DSC 10°C/min

Glass Transition Temperature

61 °C

DSC 10°C/min

Melting Temperature

150 °C

DSC, 10°C/min

Melting Temperature

150 °C

DSC, 10°C/min

Crystallization Temperature

113.5 °C

DSC 10°C/min

Crystallization Temperature

113.5 °C

DSC 10°C/min

Vicat Softening Temperature

62.9 °C

ISO 306, GB/T 1633

Vicat Softening Temperature

62.9 °C

ISO 306, GB/T 1633

Heat Deflection Temperature (1.8MPa)

58.1 °C

ISO 75, 1.8MPa

Heat Deflection Temperature (1.8MPa)

58.1 °C

ISO 75, 1.8MPa

Heat Deflection Temperature (0.45MPa)

59.8 °C

ISO 75, 0.45MPa

Heat Deflection Temperature (0.45MPa)

59.8 °C

ISO 75, 0.45MPa

Chemical Resistance

Weak Acids

Not resistant

Weak Acids

Not resistant

Strong Acids

Not resistant

Strong Acids

Not resistant

Weak Alkalis

Not resistant

Weak Alkalis

Not resistant

Strong Alkalis

Not resistant

Strong Alkalis

Not resistant

Organic Solvent

No data available

Organic Solvent

No data available

Oils and Grease

No data available

Oils and Grease

No data available

Equilibrium Water Absorption

0.51%

Equilibrium Water Absorption

0.51%

Material Guide

What feature is most important for your parts?

Recommended Materials:

Material Guide

What feature is most important for your parts?

Material Guide

What feature is most important for your parts?

Capabilities

Explore

Applications