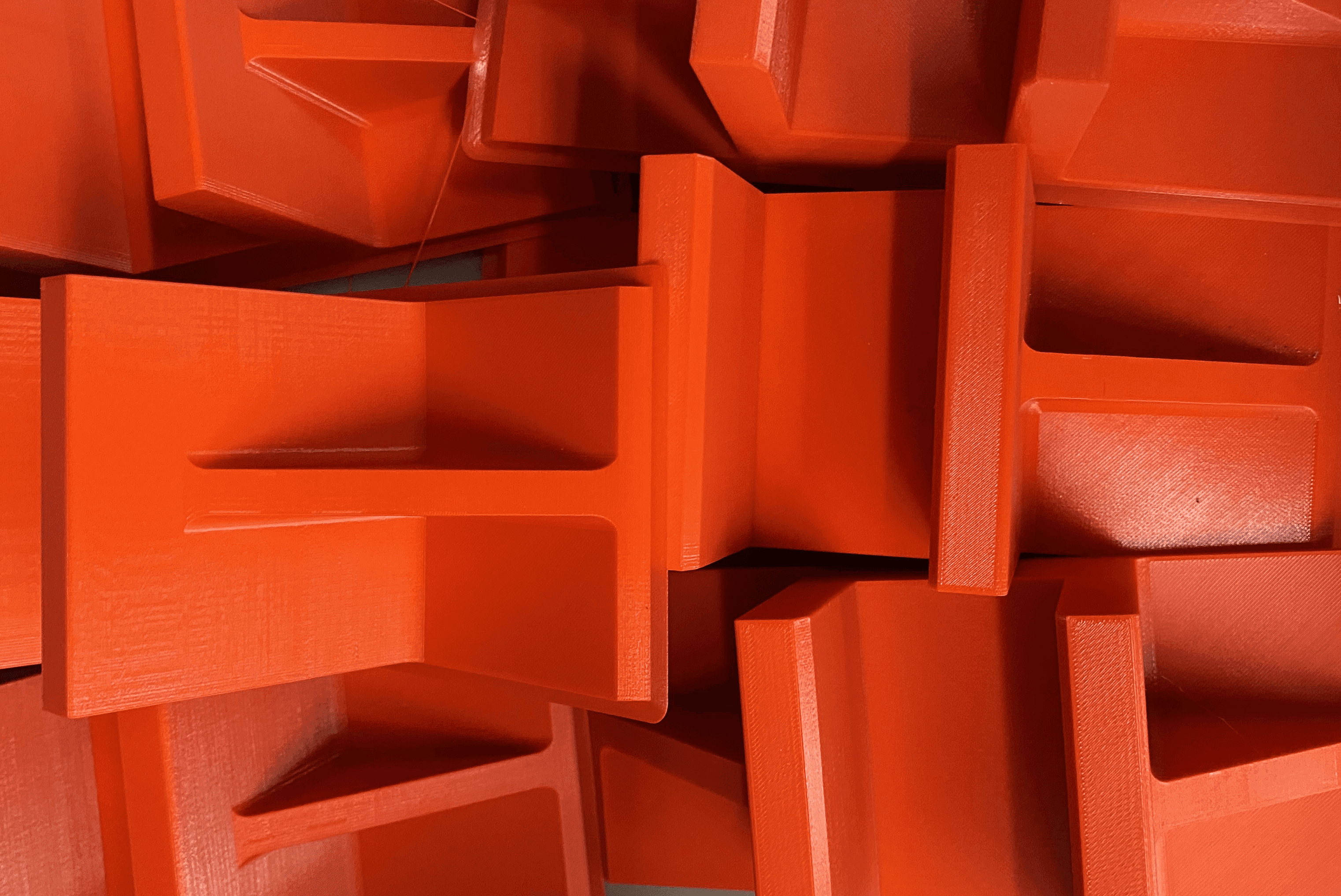

ABS

Technology:

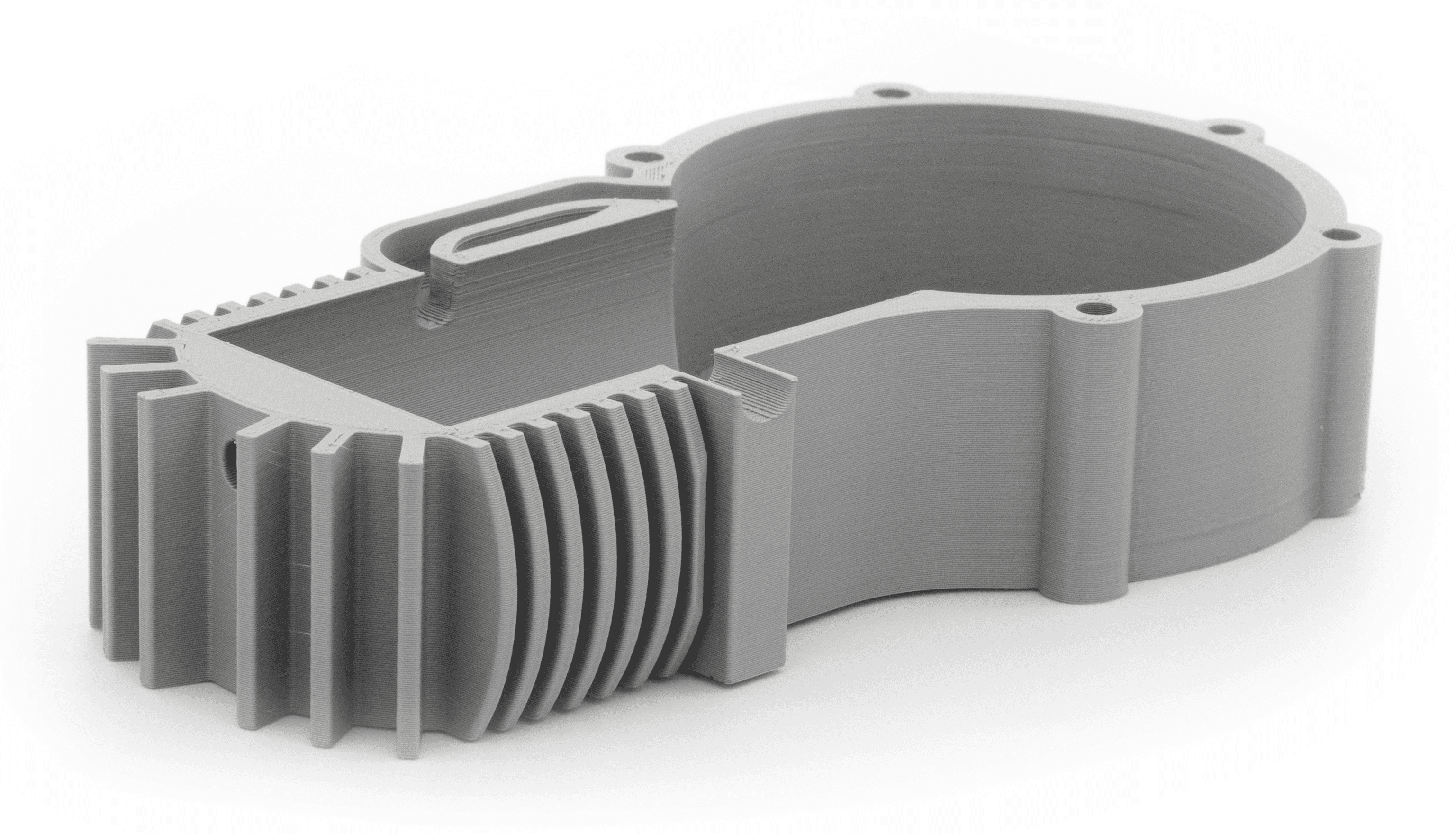

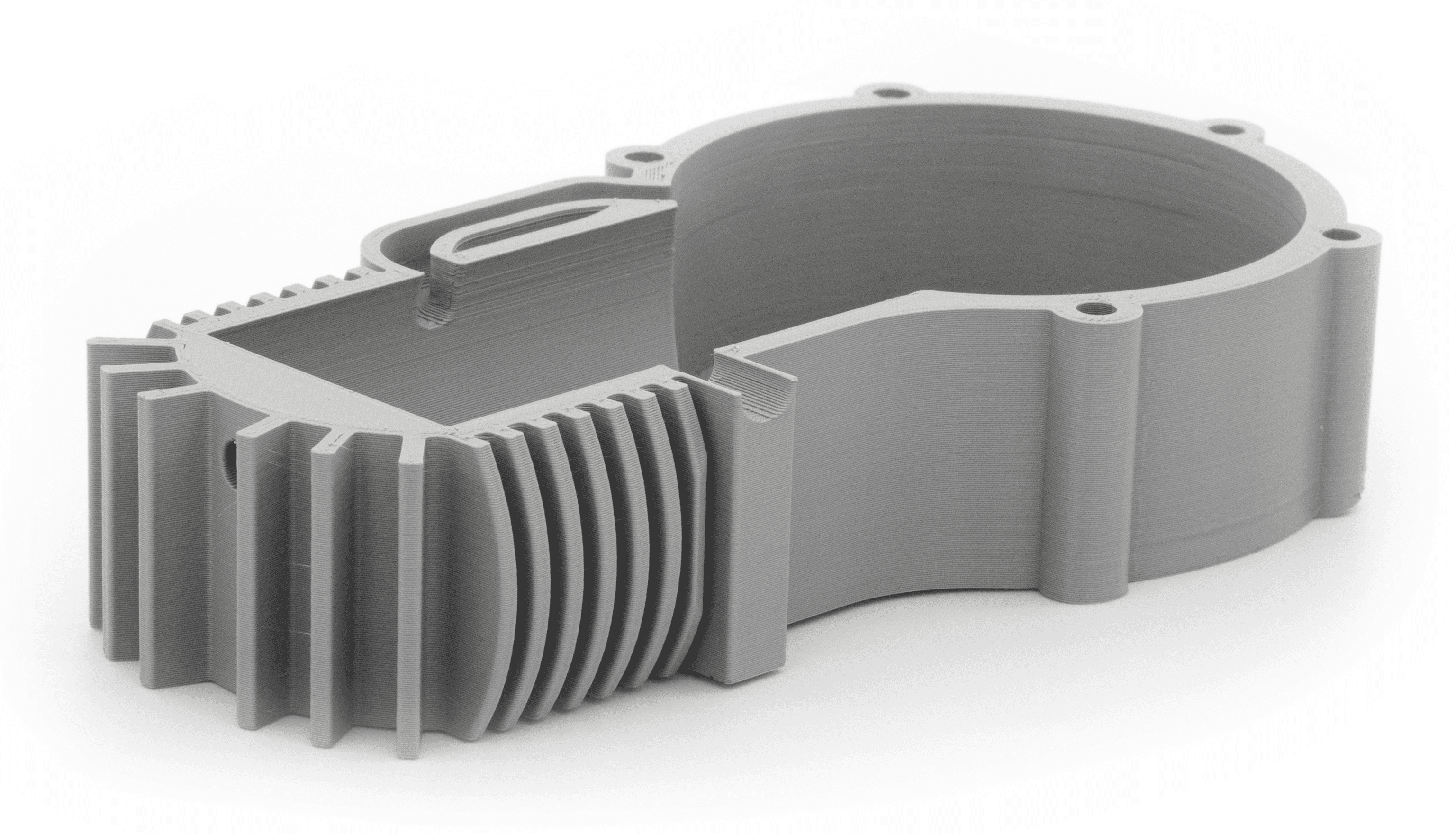

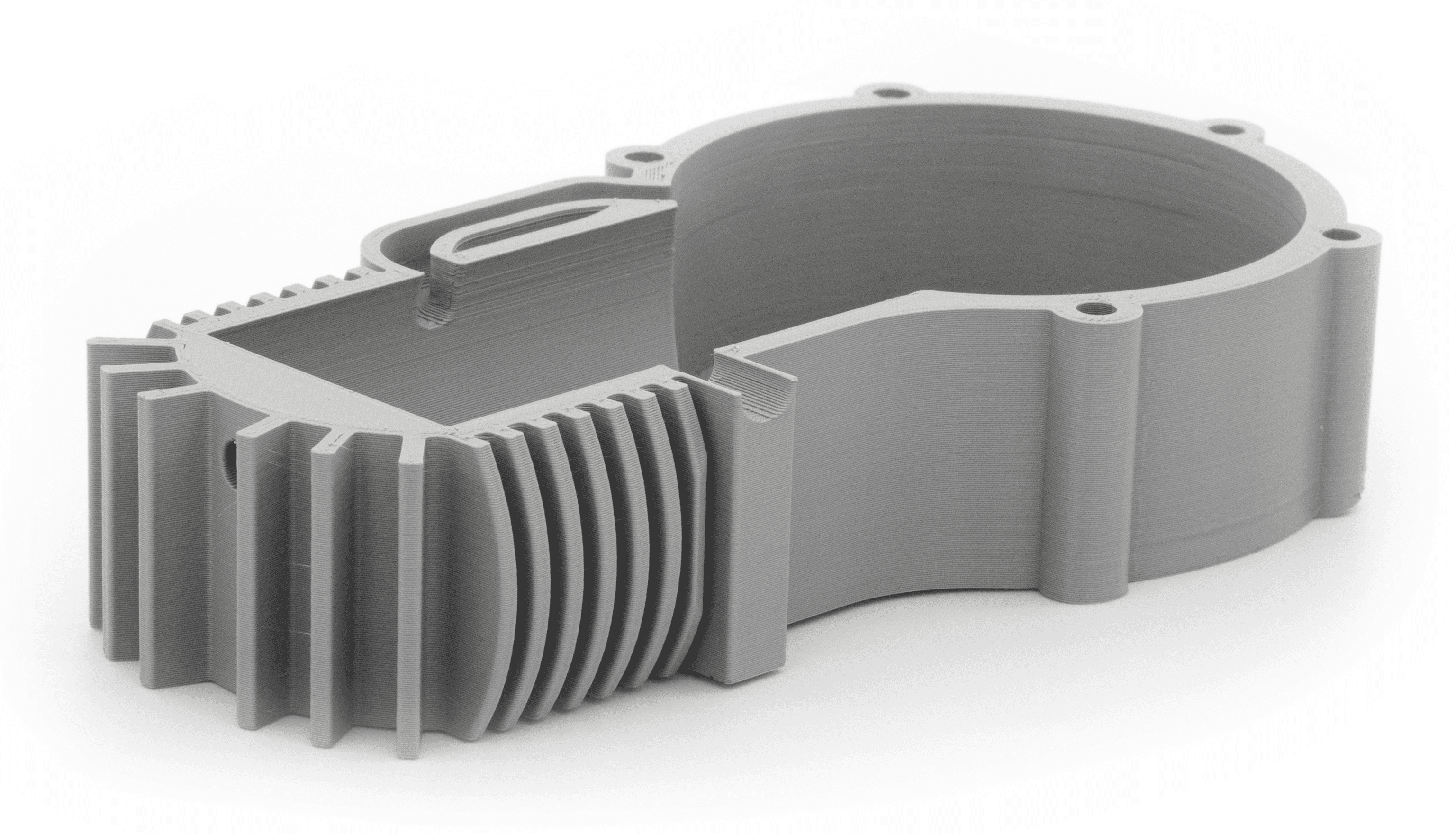

ABS is an engineering material suitable for a wide range of applications, offering moderate strength and heat resistance.

Strong

High Temperature

Impact Resistant

ABS can withstand physical stresses and strains without breaking, making it suitable for creating functional prototypes, mechanical parts, and items that will be handled or used in real-world conditions.

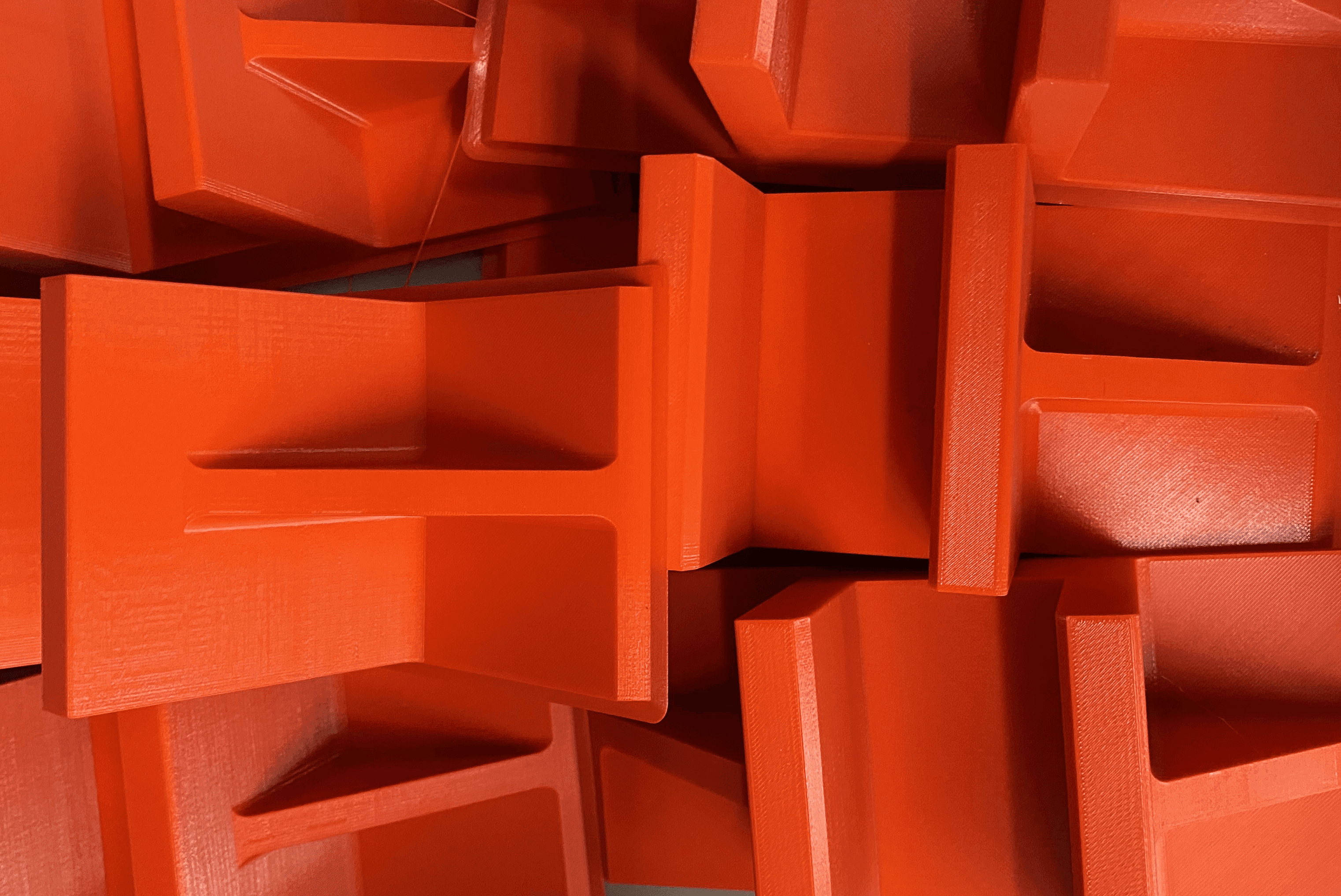

Ideal Size ≤

256 x 256 x 256 mm

(10 x 10 x 10 in)

Resolution

0.16 - 0.4 mm

Colors

Black

White

Grey

Red

Blue

Economical

Max Size

Flexibility

Strength

Heat Resistance

Economical

Label

Max Size

Label

Flexibility

Label

Strength

Label

Heat Resistance

Label

Durability and Strength

Known for its toughness and resistance to impact, ABS is ideal for parts that require high strength and durability.

Durability and Strength

Known for its toughness and resistance to impact, ABS is ideal for parts that require high strength and durability.

Durability and Strength

Known for its toughness and resistance to impact, ABS is ideal for parts that require high strength and durability.

Heat Resistance

With a higher melting point compared to PLA, ABS parts endure higher temps without deforming.

Heat Resistance

With a higher melting point compared to PLA, ABS parts endure higher temps without deforming.

Heat Resistance

With a higher melting point compared to PLA, ABS parts endure higher temps without deforming.

Chemical Resistance

ABS is resistant to many acids, alkalis, alcohols, and oils.

Chemical Resistance

ABS is resistant to many acids, alkalis, alcohols, and oils.

Chemical Resistance

ABS is resistant to many acids, alkalis, alcohols, and oils.

Compare with other

FDM

materials

Material

Economical

Max Size

Flexibility

Strength

Heat Resistance

Specifications

Mechanical Properties

Shore Hardness

~72D

ISO 7619-1, GB/T 531.1

Shore Hardness

~72D

ISO 7619-1, GB/T 531.1

(XY) Tensile Modulus

2174 ± 285 MPa

ISO 527, GB/T 1040

(XY) Tensile Modulus

2174 ± 285 MPa

ISO 527, GB/T 1040

(XY) Tensile Strength

33.3 ± 0.8 MPa

ISO 527, GB/T 1040

(XY) Tensile Strength

33.3 ± 0.8 MPa

ISO 527, GB/T 1040

(XY) Elongation at Break

2.7 ± 0.4 %

ISO 527, GB/T 1040

(XY) Elongation at Break

2.7 ± 0.4 %

ISO 527, GB/T 1040

(XY) Bending Modulus

2844 ± 411 MPa

ISO 178, GB/T 9341

(XY) Bending Modulus

2844 ± 411 MPa

ISO 178, GB/T 9341

(XY) Bending Strength

72.8 ± 0.7 MPa

ISO 178, GB/T 9341

(XY) Bending Strength

72.8 ± 0.7 MPa

ISO 178, GB/T 9341

(XY) Charpy Impact Strength

12.6 ± 1.1 kJ/m2

ISO 179, GB/T 1043

(XY) Charpy Impact Strength

12.6 ± 1.1 kJ/m2

ISO 179, GB/T 1043

Thermal Properties

Glass Transition Temperature

101.1 °C

DSC 10°C/min

Glass Transition Temperature

101.1 °C

DSC 10°C/min

Decomposition Temperature

>380°C

TGA 20°C/min

Decomposition Temperature

>380°C

TGA 20°C/min

Vicat Softening Temperature

103.9 °C

ISO 306, GB/T 1633

Vicat Softening Temperature

103.9 °C

ISO 306, GB/T 1633

Heat Deflection Temperature (1.8MPa)

98.2 °C

ISO 75, 1.8MPa

Heat Deflection Temperature (1.8MPa)

98.2 °C

ISO 75, 1.8MPa

Heat Deflection Temperature (0.45MPa)

99.6 °C

ISO 75, 0.45MPa

Heat Deflection Temperature (0.45MPa)

99.6 °C

ISO 75, 0.45MPa

Chemical Resistance

Weak Acids

Not resistant

Weak Acids

Not resistant

Strong Acids

Not resistant

Strong Acids

Not resistant

Weak Alkalis

Resistant

Weak Alkalis

Resistant

Strong Alkalis

Resistant

Strong Alkalis

Resistant

Organic Solvent

Not resistant

Organic Solvent

Not resistant

Oils and Grease

No data available

Oils and Grease

No data available

Equilibrium Water Absorption

0.35%

Equilibrium Water Absorption

0.35%

Material Guide

What feature is most important for your parts?

Recommended Materials:

Material Guide

What feature is most important for your parts?

Material Guide

What feature is most important for your parts?

Capabilities

Explore

Applications