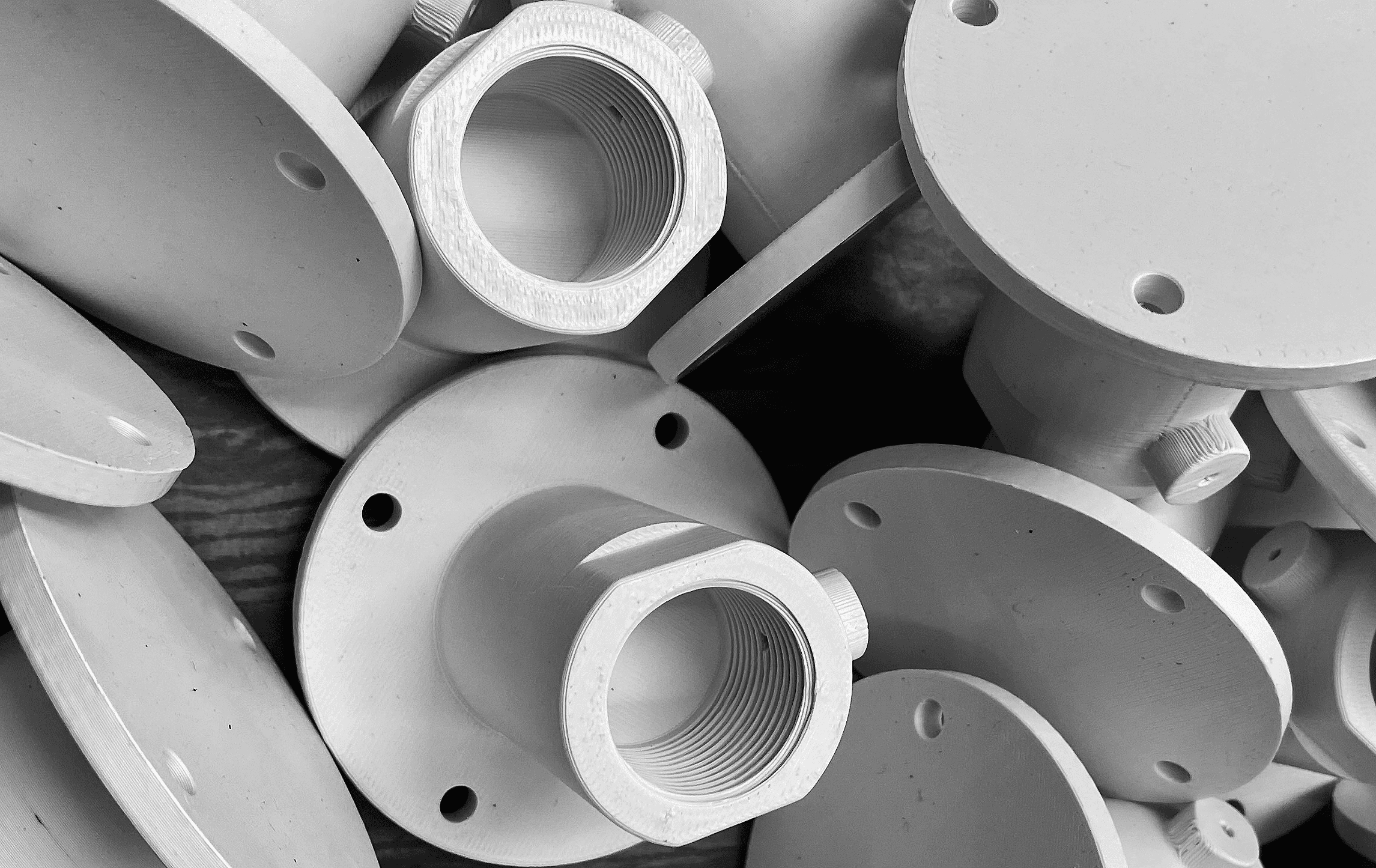

PETG

Technology:

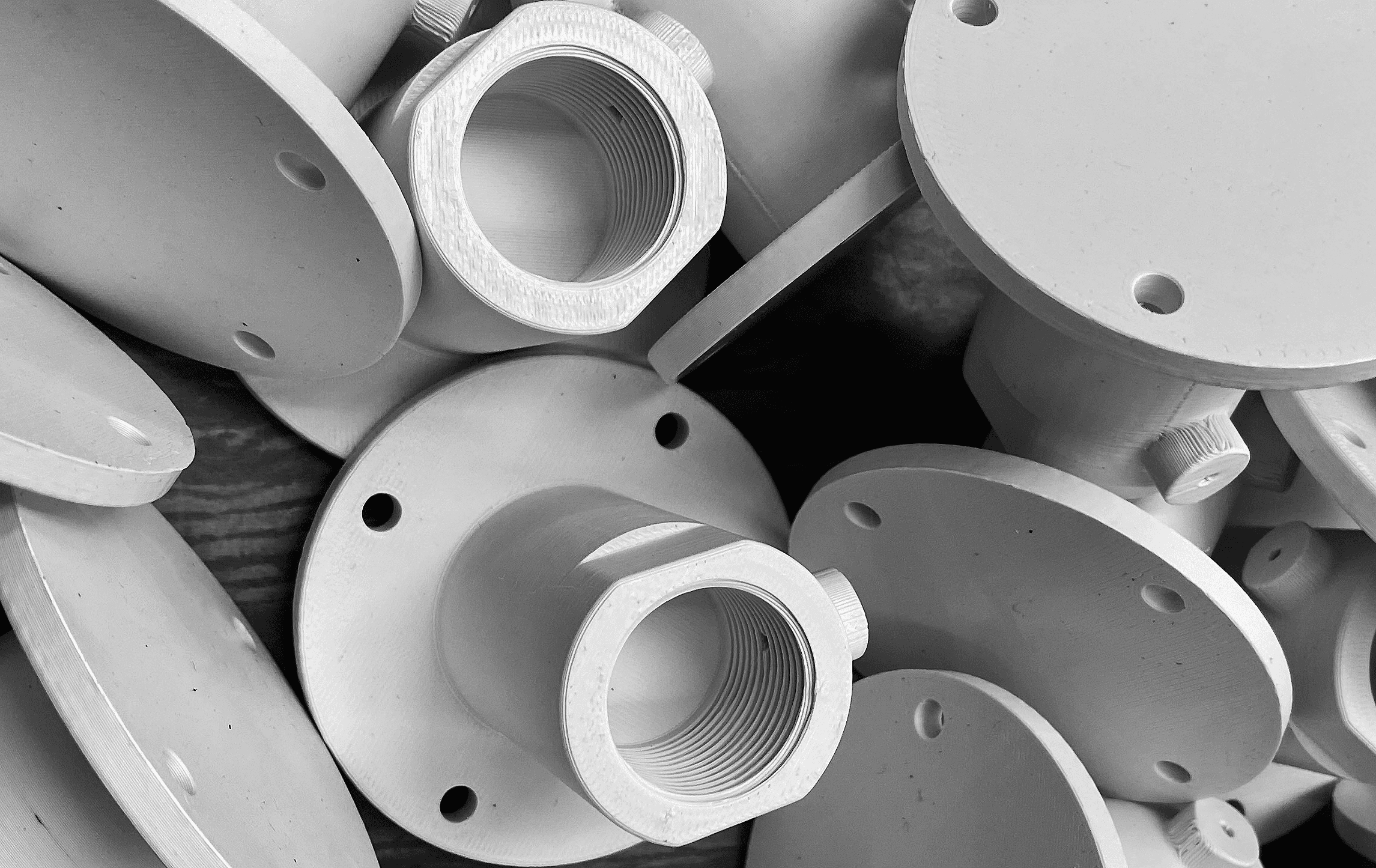

PETG is a great alternative to ABS for strong, robust, end-use parts.

Popular

Great Value

Great for Bulk Orders

If PLA does not offer the mechanical properties needed for your application, then PETG is the next step up, and our second most cost-effective option. Consider PETG for bulk orders and production runs. This engineering grade material runs beautifully across our entire print farm.

Ideal Size ≤

600 x 600 x 600 mm

(24 x 24 x 24 in)

Resolution

0.16 - 0.4 mm

Colors

White

Black

Grey

Red

Blue

Clear

Orange

Pink

Green

Teal

Purple

Economical

Max Size

Flexibility

Strength

Heat Resistance

Economical

Label

Max Size

Label

Flexibility

Label

Strength

Label

Heat Resistance

Label

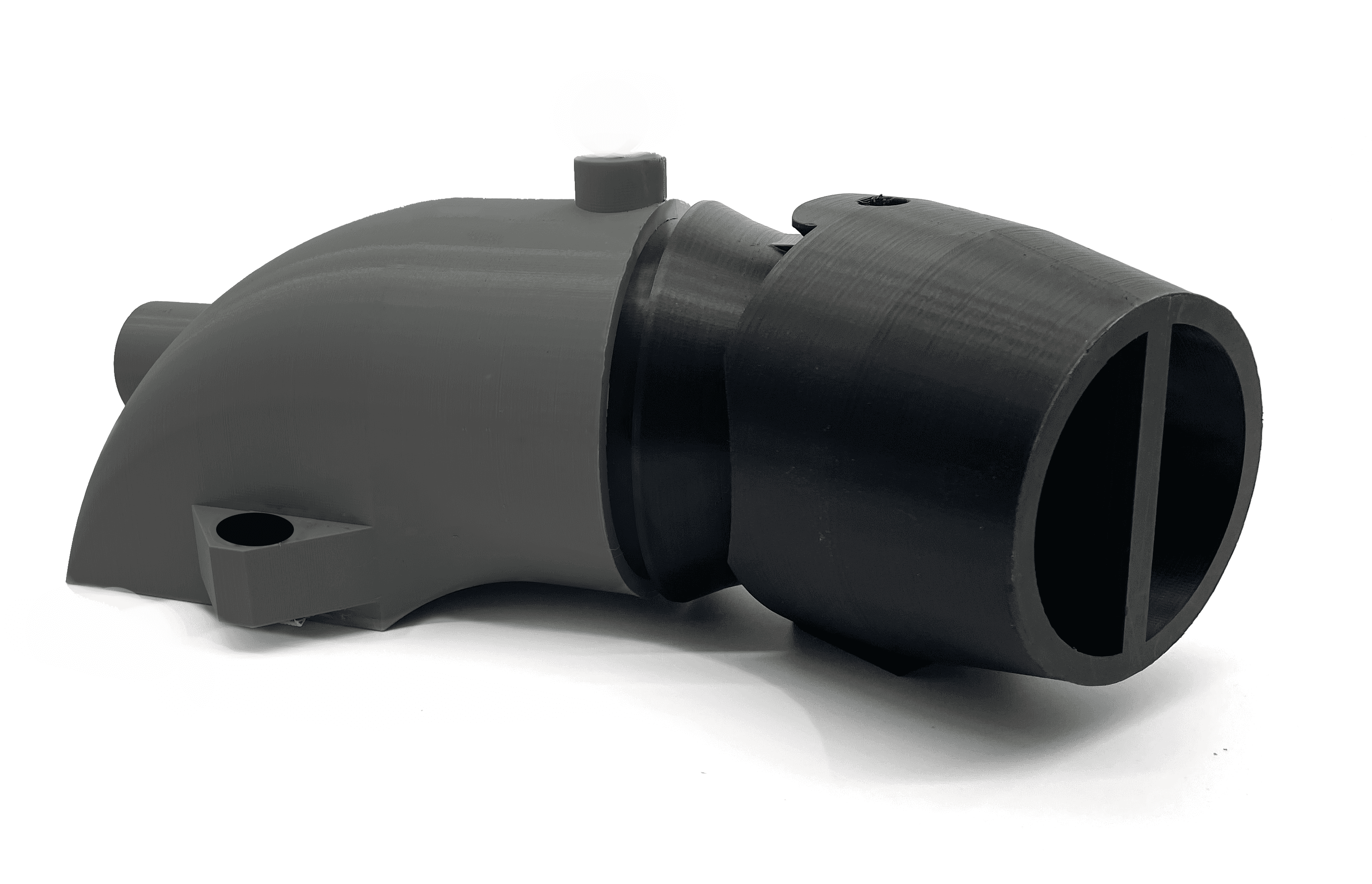

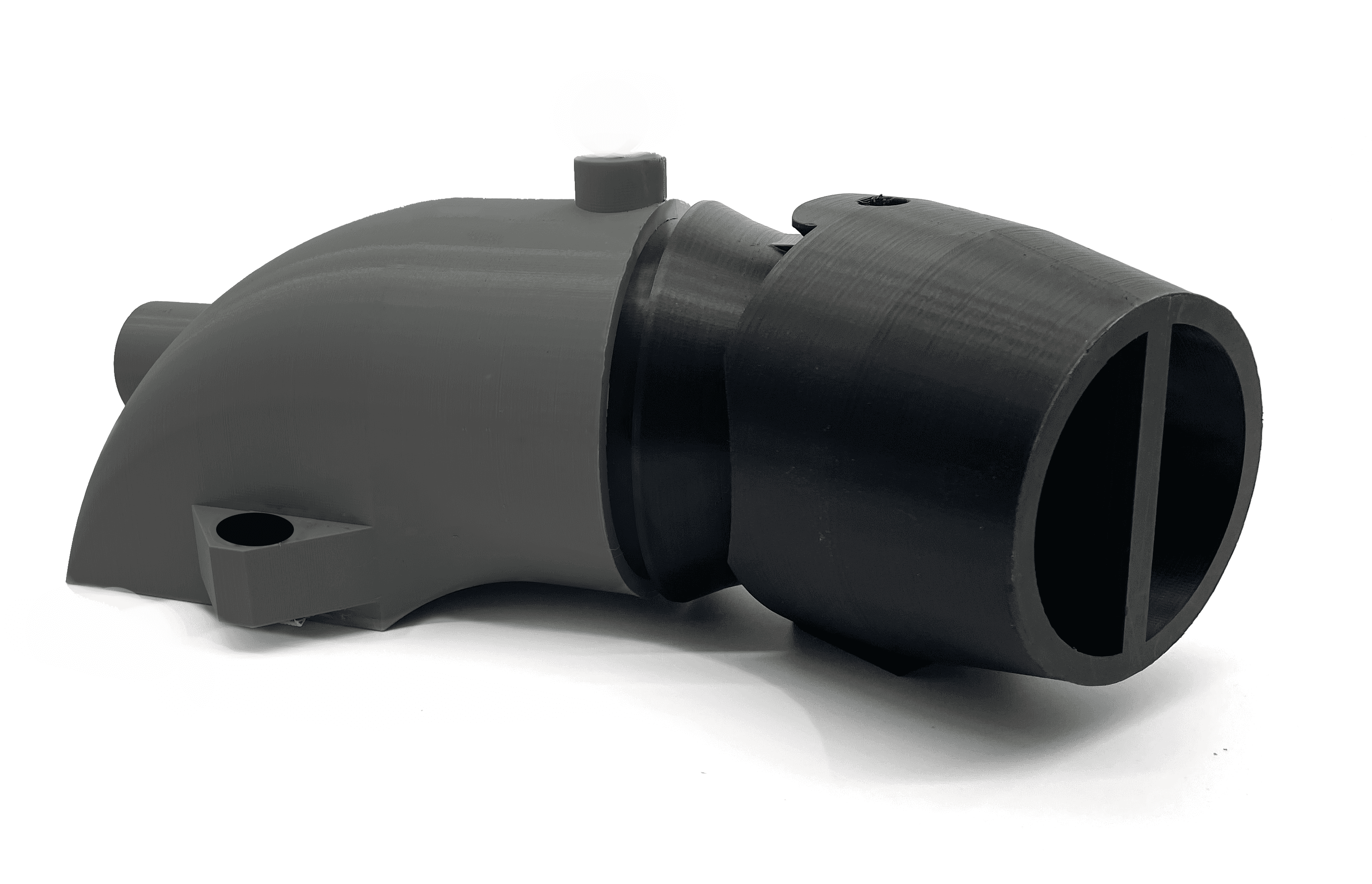

functional

Comparable properties to ABS without the risk of warping.

functional

Comparable properties to ABS without the risk of warping.

functional

Comparable properties to ABS without the risk of warping.

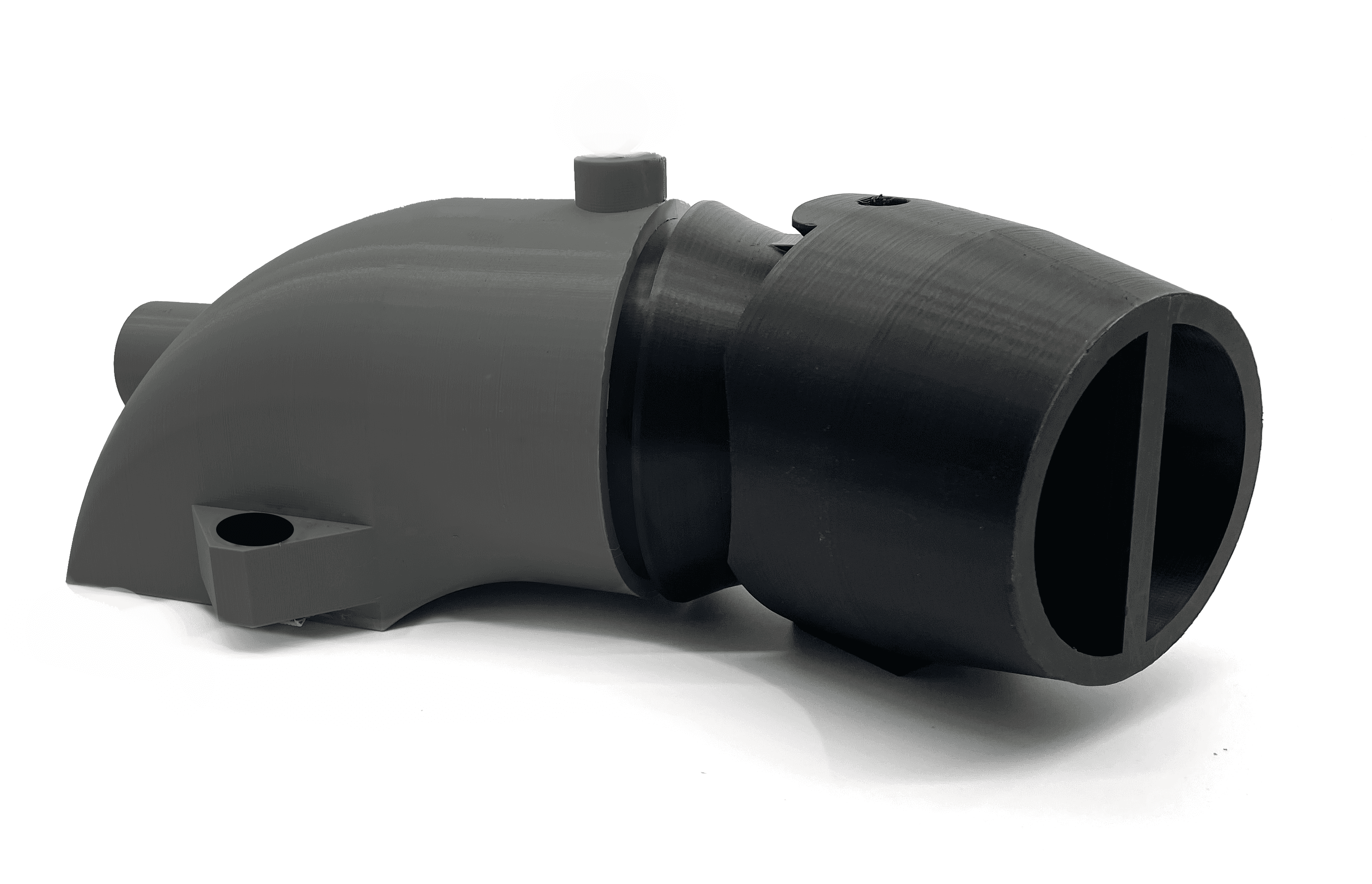

limitless complexity

Take full advantage of the design freedom 3D printing offers.

limitless complexity

Take full advantage of the design freedom 3D printing offers.

limitless complexity

Take full advantage of the design freedom 3D printing offers.

translucent options

While not fully transparent, tranlucency can be achieved.

translucent options

While not fully transparent, tranlucency can be achieved.

translucent options

While not fully transparent, tranlucency can be achieved.

Compare with other

FDM

materials

Material

Economical

Max Size

Flexibility

Strength

Heat Resistance

Specifications

Mechanical Properties

(XY) Tensile Modulus

1472 ± 270 MPa

ISO 527, GB/T 1040

(XY) Tensile Modulus

1472 ± 270 MPa

ISO 527, GB/T 1040

(XY) Tensile Strength

31.9 ± 1.1 MPa

ISO 527, GB/T 1040

(XY) Tensile Strength

31.9 ± 1.1 MPa

ISO 527, GB/T 1040

(XY) Elongation at Break

6.8 ± 0.9 %

ISO 527, GB/T 1040

(XY) Elongation at Break

6.8 ± 0.9 %

ISO 527, GB/T 1040

(XY) Bending Modulus

1174 ± 64 MPa

ISO 178, GB/T 9341

(XY) Bending Modulus

1174 ± 64 MPa

ISO 178, GB/T 9341

(XY) Bending Strength

53.7 ± 2.4 MPa

ISO 178, GB/T 9341

(XY) Bending Strength

53.7 ± 2.4 MPa

ISO 178, GB/T 9341

(XY) Charpy Impact Strength

5.1 ± 0.3 kJ/m2

ISO 179, GB/T 1043

(XY) Charpy Impact Strength

5.1 ± 0.3 kJ/m2

ISO 179, GB/T 1043

Thermal Properties

Glass Transition Temperature

81 °C

DSC 10°C/min

Glass Transition Temperature

81 °C

DSC 10°C/min

Vicat Softening Temperature

84 °C

ISO 306, GB/T 1633

Vicat Softening Temperature

84 °C

ISO 306, GB/T 1633

Heat Deflection Temperature (1.8MPa)

74.8 °C

ISO 75, 1.8MPa

Heat Deflection Temperature (1.8MPa)

74.8 °C

ISO 75, 1.8MPa

Heat Deflection Temperature (0.45MPa)

78.4 °C

ISO 75, 0.45MPa

Heat Deflection Temperature (0.45MPa)

78.4 °C

ISO 75, 0.45MPa

Chemical Resistance

Weak Acids

Not resistant

Weak Acids

Not resistant

Strong Acids

Not resistant

Strong Acids

Not resistant

Weak Alkalis

Not resistant

Weak Alkalis

Not resistant

Strong Alkalis

Not resistant

Strong Alkalis

Not resistant

Organic Solvent

Resistant most

Organic Solvent

Resistant most

Oils and Grease

No data available

Oils and Grease

No data available

Equilibrium Water Absorption

0.54%

Equilibrium Water Absorption

0.54%

Material Guide

What feature is most important for your parts?

Recommended Materials:

Material Guide

What feature is most important for your parts?

Material Guide

What feature is most important for your parts?

Capabilities

Explore

Applications